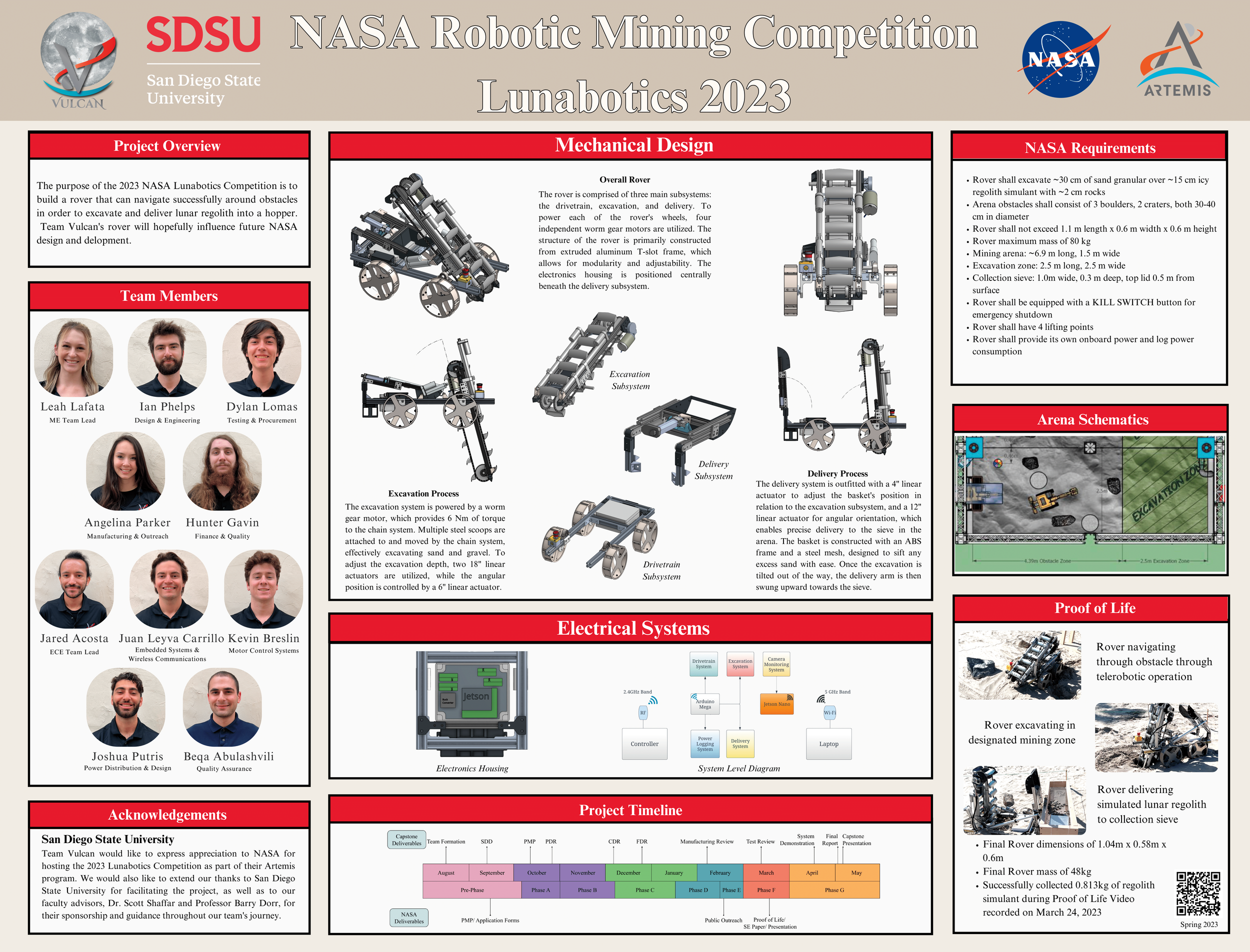

NASA Lunabotics Competition

In this competition university students develop lunar rovers to influence future NASA design and development.

2023s challenge was to create a rover that could navigate an obstacle course, excavate, and then deliver icy lunar regolith.

Design Lead

-

Sketch

My role in the project began with sketching out design paths that could be undertaken with various budgets. In this stage I divided the rover into the subsystems that would later enable co-development and integration.

-

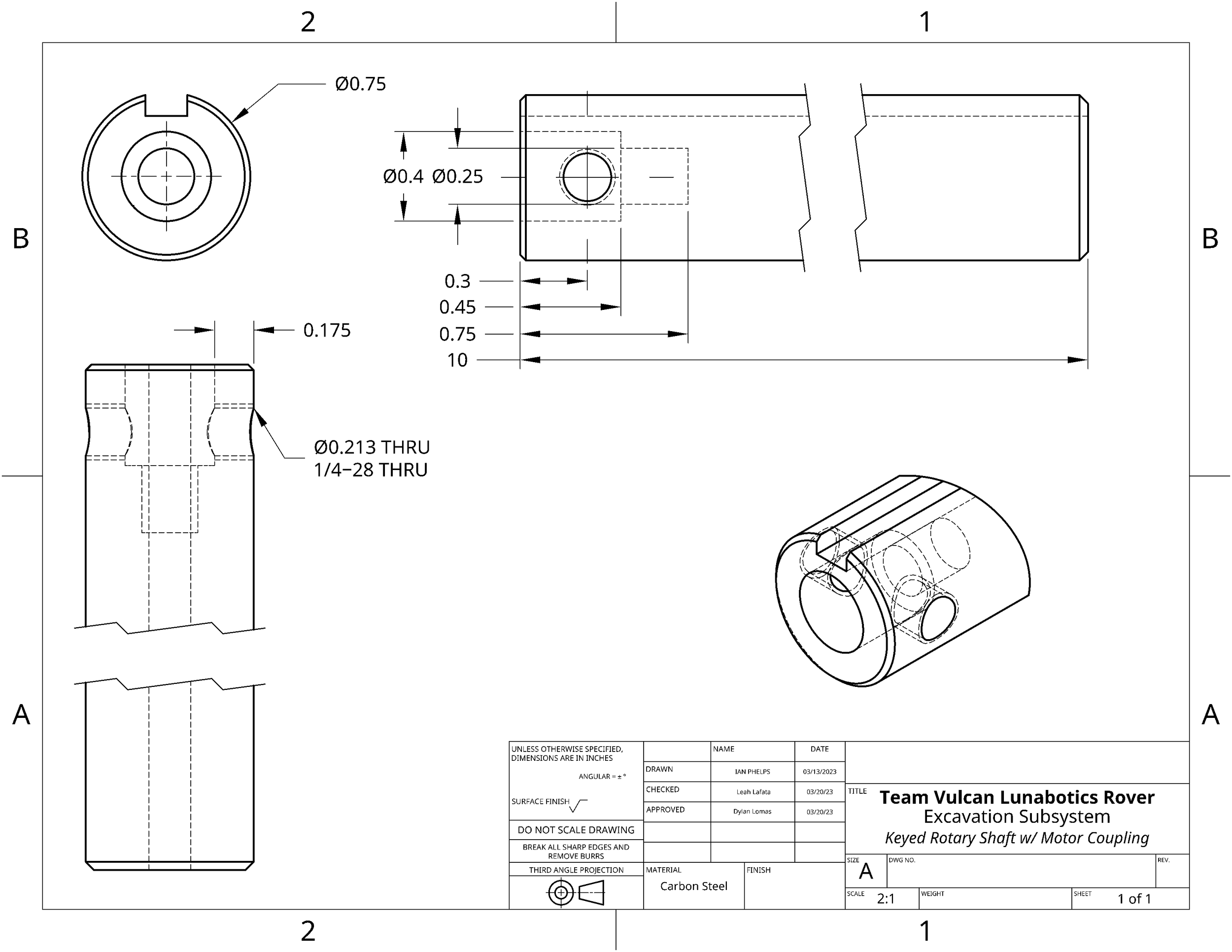

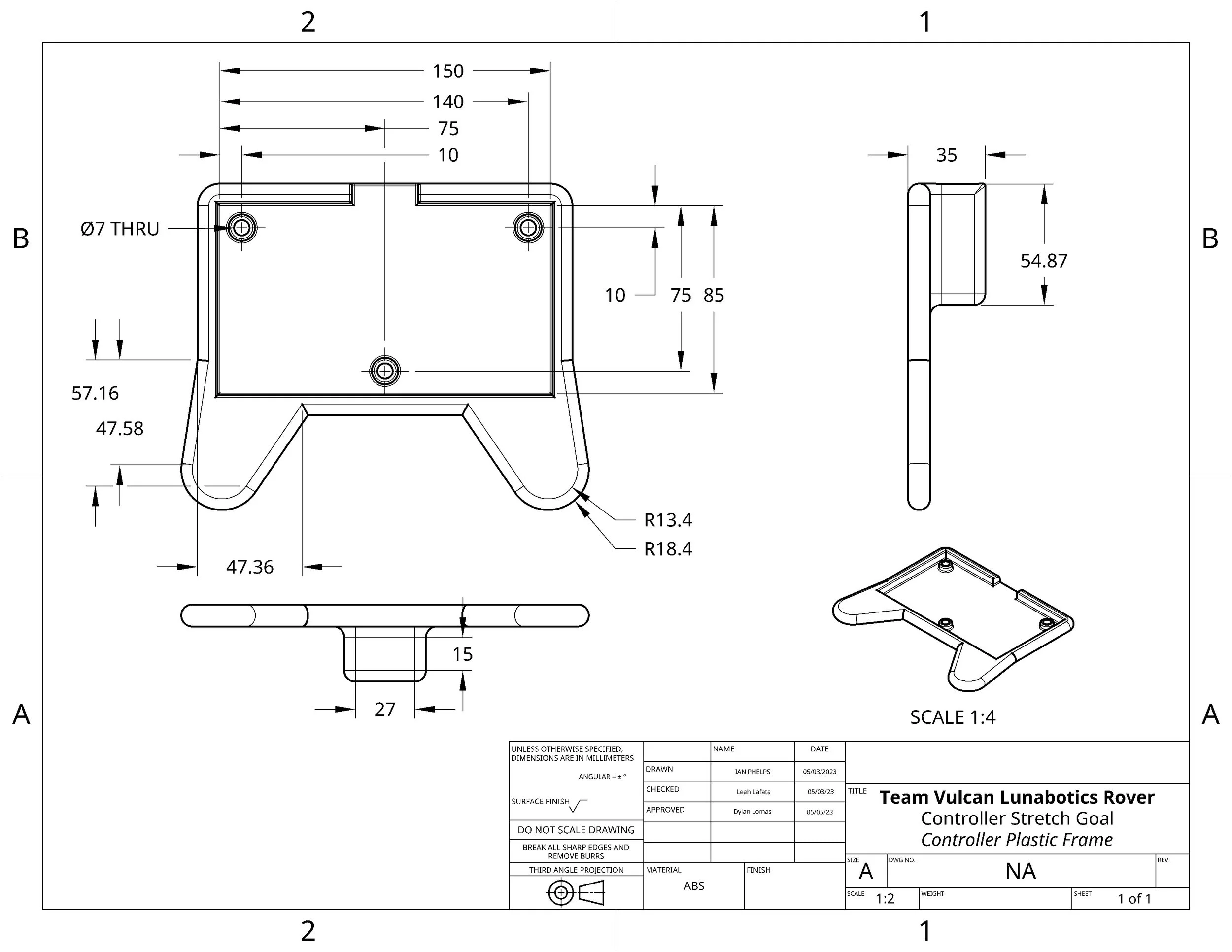

CAD

To better understand the physical implementations of the overall design I created multiple components and assemblies to allow for detailed analysis and presentation. With this, physical limitations could be understood, and with the design branch system I used modifications were quickly tested for viability.

-

Manufacture

Once a design and budget were confirmed I quickly went about ordering components of the system. As soon as the machine shop was open at the university I milled components to allow for expedited testing of our fixtures as our timeline was incredibly short.

-

Assemble

Our weeks in the lab lead to an assembled rover that could be tested with fully integrated electronics and data capture. In this form electronic and mechanical shortcomings could be understood. I adapted the design of various components and quickly implemented the improvements leading to the rovers incredible success.

The Vulcan Rover

Comprising three main subsystems—drivetrain, excavation, and delivery—the rover is constructed with a modular design of extruded aluminum to allow for adjustability.

Rover Maneuverability

The drivetrain was made of four independent motors in a tank-like configuration, no suspension or steering rack needed. The camera at the top of the excavation system allowed for sight of what was ahead of the rover.

The excavations subsystem was powered by a worm gear motor ensuring the needed torque applied to the chain scoop system. The driving force of the depth of excavation system were dual 18” linear actuators that drove the scoops deep into the ground to the required depth of the competition. The scoops deposited the regolith into the delivery system at each rotation. The delivery basket adjusted its position based on the depth of the system at the time.

The Excavation Process

Awards & Recognitions

-

Against more than 30 universities across the country, with my small team at SDSU we placed an unprecedented second place overall

-

In the first time for the category to be included in the competition our proof of life of video proved to be the best of the whole year.

-

With placement in all three of these categories the team received $5000 in total winnings.